Proper Water Management Is In The Details

A common trend in architectural detailing is to draw a sill flashing with an upturn leg at curtain wall sill conditions. The concept of a sill flashing being used in this fashion originates with their use in storefront systems. When the storefront framing is installed, it is held in place by clips only, and does not penetrate the sill flashing extrusion in any way. This is an acceptable method for utilizing a sill flashing – for storefront system applications.

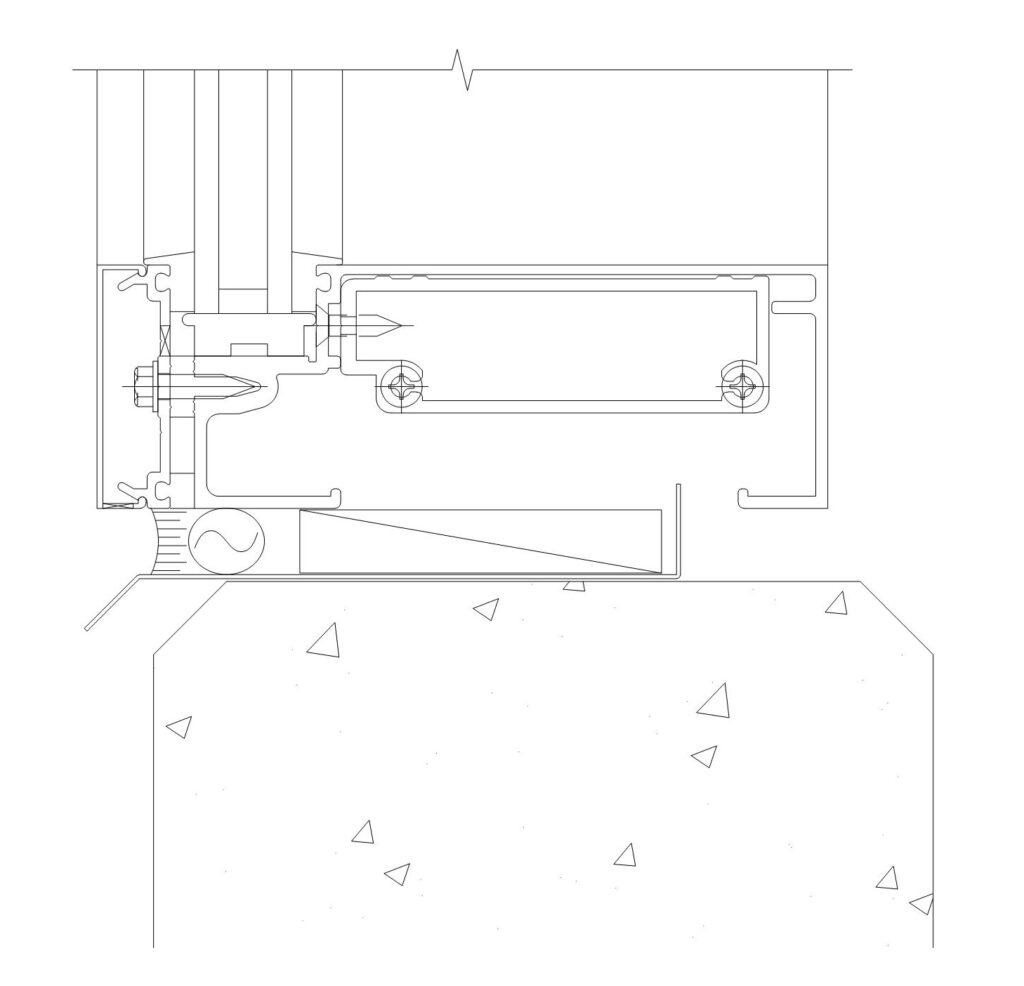

This method does not work the same way for curtain wall applications. Nonetheless, curtain wall details such as the one below are commonly found in architectural drawings, which can be problematic.

For curtain wall systems that do not include a sill flashing extrusion as part of the system, a detail such as this can pose the following problems:

1) Additional Joints

There are now two joints that become critical to maintain the system’s waterproofing integrity: the perimeter joint, as well as the bed of sealant that the sill flashing is set on to. If a system does not have a sill flashing extrusion that is provided by the system manufacturer, then the sill flashing is not integral to the functionality of the system, and additional testing may be required.

2) Compatibility Issues

In some cases a sill flashing piece may be required due to the substrate the system is attaching to. An example would be if a waterproofing membrane was being used on the substrate that was not compatible with the perimeter caulking. In a case such as this, a sill flashing could serve the function of marrying the waterproofing to the curtain wall system by setting the flashing into a bed of sealant that is compatible with the membrane and then caulking the curtain wall to the flashing, allowing compatibility on both sides of the flashing. While this is an option, it requires additional steps which equates to more cost.

3) Sealing Challenges

When a sill flashing is required to be used, an upturn leg as shown on the detail above would not provide the benefit of additional waterproofing support as intended due to the following:

A) Curtain wall systems, or any other systems that do not have an integral sill flashing design, will require penetrations to be made with the fasteners through the sill flashing. These penetrations are often made for fastening “F” or “T” clips that attach the curtain wall verticals to the substrate. In most cases these clips are

pre-installed on the verticals, which means gaining access to seal the fastener or the perimeter of the clip would be extremely limited and would most likely require a blind seal.

B) Assuming penetrations could be sealed, the function of the upturn leg would then become the question. The intention of the upturn leg is to stop any water that passes the perimeter caulk joint. If water were to pass the perimeter caulk joint, it would be trapped by the upturn leg and a method for expelling that water would need to be developed.

C) If the intention is to only trap the water, than an interior caulk joint as detailed above would serve that purpose more efficiently. It is not a good practice to rely on trapping water as part of the water infiltration management program.

4) Maintenance Considerations

Maintainability is also a factor that should be considered with the design of a sill condition. Repairing or replacing a perimeter caulk joint is feasible, however, when a flashing is introduced, the bed of sealant that the flashing rests on is not a serviceable joint. If failures arise in the bed of sealant, repair or replacement becomes much more difficult.

In Summary

The preferred method for a system that does not have an integral sill flashing incorporated into the manufacture’s design is to eliminate the sill flashing altogether and seal to the substrate directly. In some cases this is not an option due to compatibility or aesthetic reasons. In these situations a sill flashing would have to be used and great care would need to be taken to ensure that the flashing is set in an adequate bed of compatible sealant and fastened sufficiently. Upturn legs should not be included in the design of the sill flashing because it creates additional joints, compatibility issues, sealing challenges, and maintenance considerations.

Water management is one of the most critical issues that an architect or contractor must consider when selecting a glazing system. Kovach is here to help you select or design the right system for your project.